Belt conveyor drive pulley with rubber or ceramic lagging

- group name

- Pulley

- Min Order

- 2 piece

- brand name

- SKE

- model

- B400/B500/B650/B800/B1000/B1200/B1400/B1600

- Nearest port for product export

- Shanghai,China

- Delivery clauses under the trade mode

- FOB, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Westem Union

- update time

- Wed, 24 Jun 2020 10:38:18 GMT

Paramtents

Color Black /Blue/ Grey/Green/Red

Lagging rubber or ceramic lagging

Diamter 250-1600

Weight 98-9800 kgs

Packging & Delivery

-

Min Order2 piece

Briefing

The transmission Pulley is a component that transmits power to the conveyor.

Detailed

Description

Belt conveyor drive pulley with rubber or ceramic lagging: The transmission Pulley is a component that transmits power to the conveyor. It is a component that drives the belt to run by the friction between the belt and the conveyor. The driving method of the belt conveyor is divided into single pulley, double pulleys and multiple pulleys. The surface of the transmission pulley has exposed smooth steel surface, normal chevron and diamond pattern rubber covering. The steel exposed pulley can be used when it is a low power, small bandwidth and dry environment. Normal chevron rubber surface has a large coefficient of friction, good slip resistance and drainage, but it has directionality. Diamond pattern rubber surface can be used for two-directions conveyors.

Application

The drive pulleys are widely used in belt conveyors, bearing seat is divided into integral type and split type;

Features

1. Simple and compact structure and occupied a small area of space;

2. Well sealed, suitable for workplaces with large dust concentrations and wet muddy places;

3. Easy to be used and maintained, safe and reliable operation, and long life;

4. Less energy and is easy to implement centralized control;

5. Meet various requirements of backstop, braking, and rubber packing;

6. Take anti-rust and protection measures on the drive Pulley shaft head.

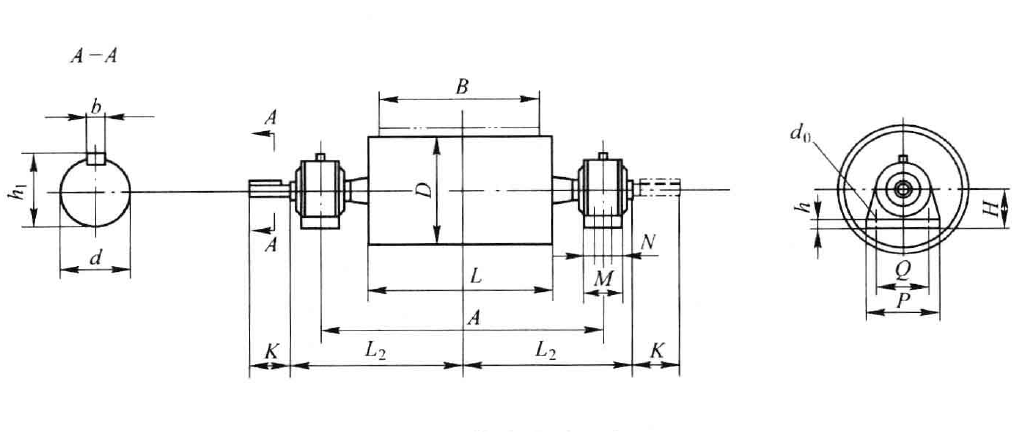

Simple drawing of Drive Pulley

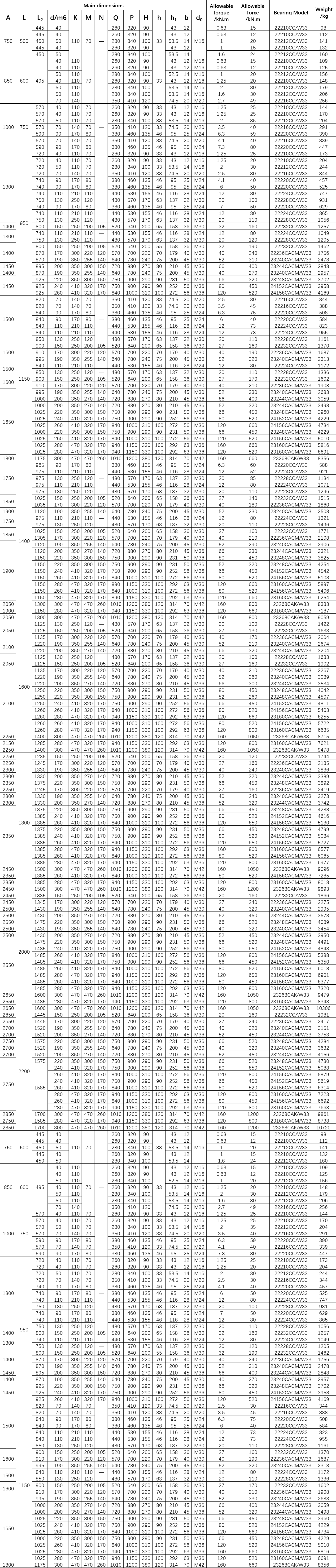

Specifications