DTII (A )Type Fixed Belt Conveyor used in metallurgy, mines, coal, power station, building materials

- group name

- Fixed Belt Conveyor

- Min Order

- 1 set

- brand name

- SKE

- model

- B500/B650/B800/B1000/B1200/B1400/B1600

- Nearest port for product export

- Shanghai,China

- Delivery clauses under the trade mode

- FOB, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Westem Union

- update time

- Wed, 17 Jun 2020 16:35:33 GMT

Paramtents

Color Customized

Application aggregate/ mix batch plant/ grain/coal etc

Packging & Delivery

-

Min Order1 set

Briefing

DT II (A) belt conveyor is a stationary belt conveyor based on application and user's experience and requirement;

Detailed

Description

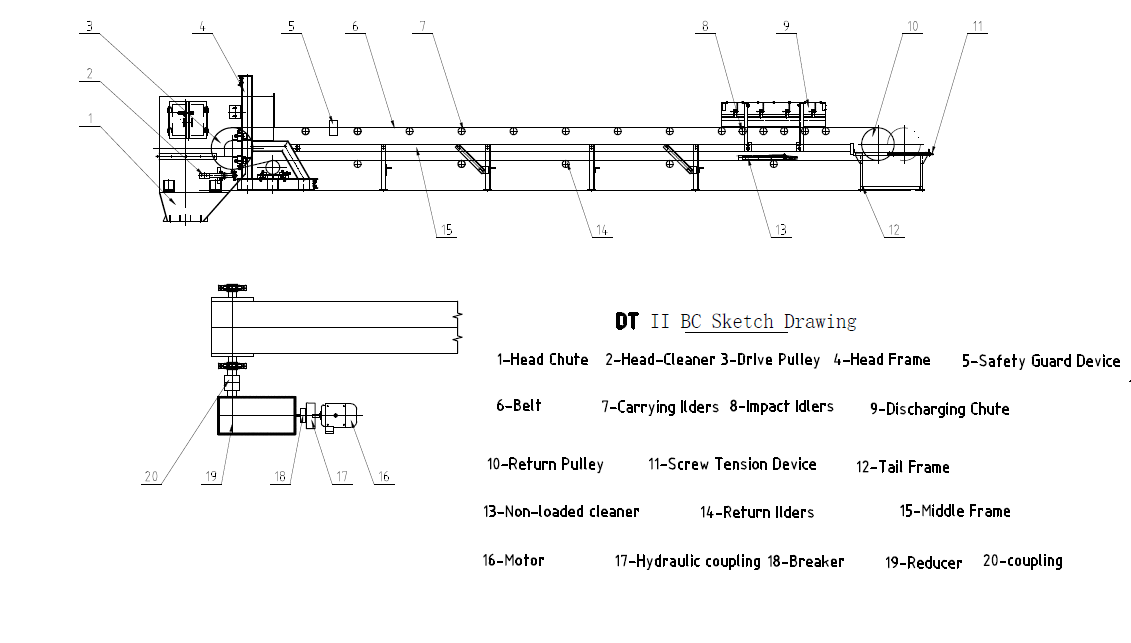

DTII (A )Type Fixed Belt Conveyor used in metallurgy, mines, coal, power station, building materials:According to the application of DT II series belt conveyor in the past and the user's experience and requirements, the DT II (A) sreries belt belt conveyors have expanded the variety and specification of the parts, improved the structure of the parts. The bearing, fastener, special material, manufacturing and assembly technology used in the modified design are all in accordance with the latest national standards. Because the supplementary design is quite different from the original design, it is named DT Ⅱ (a) belt conveyor.

The complete conveying sustem is suposed to be designed by single or multi units. It can convey various bulk materials with a bulk density of 500-2500kg / m3. The applicable ambient temperature is - 25 ℃ ~ + 40 ℃. For the belt conveyor working in special environment, the conveyor belt is required to be heat resistance, cold resistance, water resistance, corrosion protection, explosion-proof, flame-retardant, etc., meanwhile the corresponding protective measures shall be taken separately. This series of belt conveyor is designed according to the parts, which has high universality.

SKE can carry out the free detailed design of the conveyor according to the flow diagram provided by the customer, and provide the calculation sheet, general drawing, parts list, foundation size, foundation load and other data to the customer and the Design Institute in a short period, or carry out the design after the data is inspected on site.

Application

It can be widely used in metallurgy, mines, coal, ports, power stations, building materials, chemical industry, light industry, machinery, petroleum and other industries.

DTT II Main components

Features

1)A wide range of conveying materials

2)Wide range of conveying capacity

3)Strong adaptability of conveying line

4)Flexible loading and unloading

5)Strong reliability

6)Low maintenance costs

7)Strong reliability

8)High safety

Technical Specifications

Width | Capacity IV (m3h) |

|||||||||||

Speed V (m/s) |

||||||||||||

0.8 | 1.0 | 1.25 | 1.6 | 2.0 | 2.5 | 3.15 | 4.0 | (4.5) | 5.0 | (5.6) | 6.5 | |

500 | 69 | 87 | 108 | 139 | 174 | 217 | -- | -- | -- |

-- |

-- |

-- |

650 | 127 | 159 | 198 | 254 | 318 | 397 | -- | -- | -- | -- | -- | -- |

800 | 198 | 248 | 310 | 397 | 496 | 620 | 781 | -- | -- | -- | -- | -- |

1000 | 324 | 405 | 507 | 649 | 811 | 1014 | 1278 | 1622 | -- | -- | -- | -- |

1200 | -- | 593 | 742 | 951 | 1188 | 1486 | 1872 | 2377 | 2674 | 2971 | -- | -- |

1400 | -- | 825 | 1032 | 1321 | 1652 | 2065 | 2602 | 3304 | 3718 | 4130 | -- | -- |

1600 | -- | -- | -- | -- | 2186 | 2733 | 3444 | 4373 | 4920 | 5466 | 6122 | -- |

1800 | -- | -- | -- | -- | 2795 | 3494 | 4403 | 5591 | 6291 | 6989 | 7829 | 9083 |

2000 | -- | -- | -- | -- | 3470 | 4338 | 5466 | 6941 | 7808 | 8676 | 9717 | 11277 |

2200 | -- | -- | -- | -- | -- | -- | 6843 | 8600 | 9776 |

10863 |

12166 |

14120 |

Note:

1. The delivery capacity ( IV ) is calculated according to the attribute transportation when the dynamic stacking angle is 20 ° and the idler groove angle is 35 °

2. The belt speed (4.5) and (5.6) m / s in the table are non-standard values, which are generally not recommended.