How to install a belt conveyor?

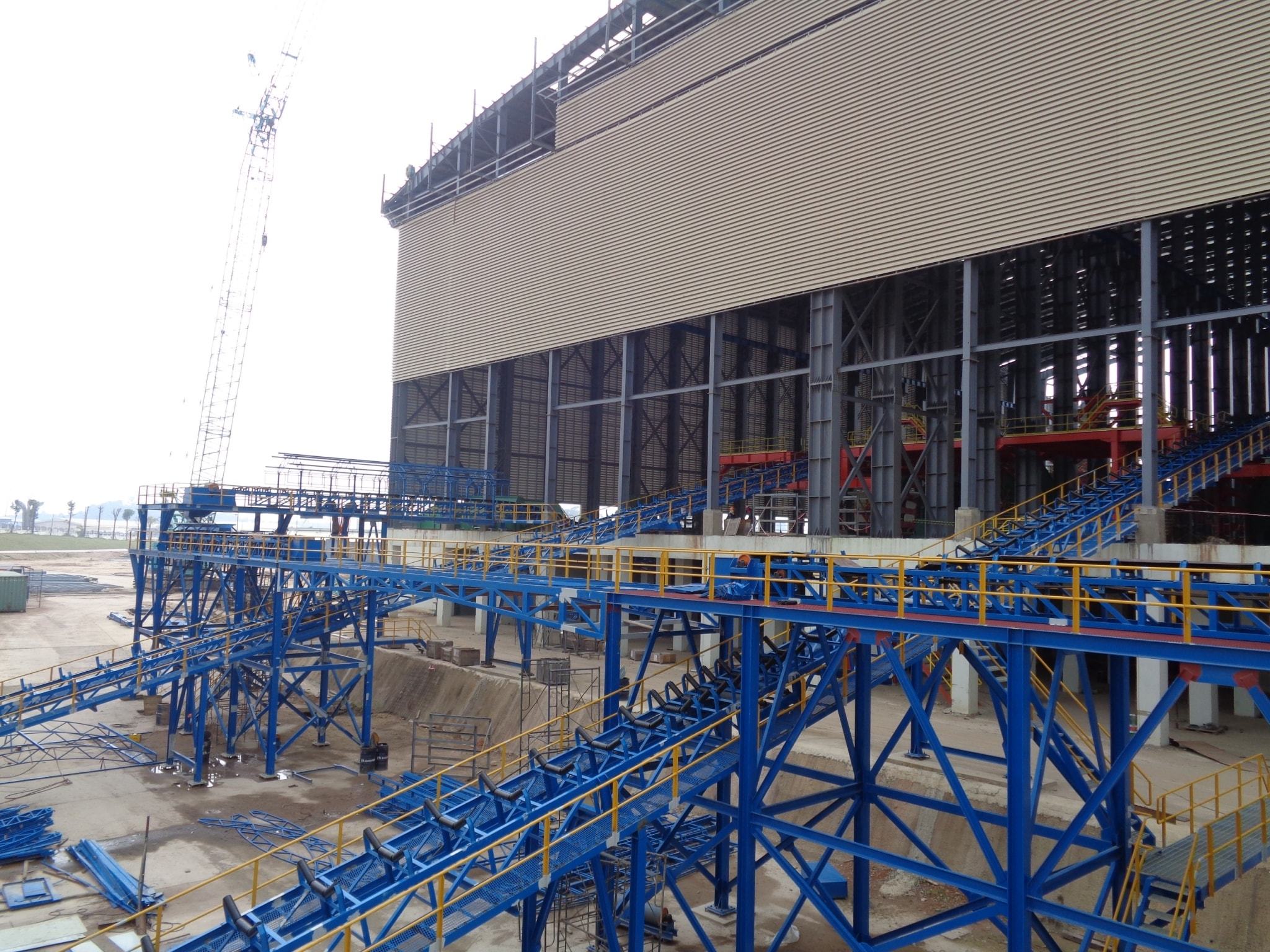

Belt conveyors, as a bulk material handling solution, are now more and more popularly used in many different fields; How to install a belt conveyor is quite important, SKE machinery company as professional belt conveyor manufacturer and supplier in Shanghai,China, has many years experience in installation engineering; The installation of belt conveyor is generally carried out in the following stages.

1. The installation of the rack frame of the belt conveyor starts from the head frame, then the middle frames of each section are installed in sequence, and finally the tail frame is installed. Before installing the rack, the center line must be drawn over the entire length of the conveyor. Since keeping the center line of the conveyor in a straight line is an important condition for the normal operation of the conveyor belt, it is necessary to install each section of the rack. Align the center line, and at the same time set up a rack to level it. The allowable error of the rack to the center line is ±0.1mm per meter. However, the error of the center of the frame over the overall length of the conveyor shall not exceed 35mm. After all the single sections are installed and identified, the single sections can be connected.

2. When installing the drive device, you must pay attention to make the drive shaft of the belt conveyor perpendicular to the center line of the belt conveyor, so that the center of the width of the drive pulley coincides with the center line of the conveyor, and the axis of the reducer and the drive axis parallel. At the same time, all shafts and rollers/pulleys should be leveled. The horizontal error of the shaft is allowed within the range of 0.5-1.5 mm according to the width of the conveyor. While installing the drive device, you can install the tail wheel and other tensioning devices. The roller/pulley axis of the tensioning device should be perpendicular to the center line of the belt conveyor.

3,Install the idlers. After the frame, transmission device and tensioning device are installed, theidler racks of the upper and lower idlers can be installed, so that the conveyor belt has a curved arc that changes slowly, and the distance between the idler racks in the turning section is normal. 1/2~1/3 of the idler frame spacing. After the idler is installed, make its rotation flexible and brisk.

4. The final alignment of the belt conveyor In order to ensure that the conveyor belt always runs on the center line of the idler and pulley, the following requirements must be met when installing the idler, frame and pulleys:

1) All idlers must be arranged in a row, parallel to each other, and kept horizontal.

2) All the pulleys are arranged in a row, parallel to each other.

3) The supporting structure frame must be straight and keep horizontal. For this reason, after the installation of the drive pulley and the supporting idler frame, the final correction should be made to the center line and level of the conveyor.

5. Then fix the rack on the foundation or floor. After the belt conveyor is fixed, feeding and unloading devices can be installed.

6. Hanging the conveyor belt When hanging the conveyor belt, first spread the conveyor belt strips on the idlers of the unloaded section, enclose the driving pulley, and then lay them on the idlers of the heavy-duty section. The 0.5-1.5 tons hand winch can be used for hanging the belt. When tightening the belt for connecting, the pulley of the tensioning device should be moved to the limit position, and the trolley and the spiral tensioning device should be pulled toward the transmission device; and the vertical picking device should move the pulley to the top . Before tightening the conveyor belt, the reducer and motor should be installed, and the braking device should be installed on the inclined conveyor.

7. After the belt conveyor is installed, a non-loading test is required. During the test, pay attention to whether there is deviation phenomenon in the operation of the conveyor belt, the operating temperature of the driving part, the activity of the idler during operation, the degree of contact between the cleaning device and the guide plate and the surface of the conveyor belt, etc. Make necessary adjustments, and the test with load can be carried out after all parts are normal. If a screw-type tensioning device is used, the tightness must be adjusted again when running the test machine with load.